Bulk cement tanker trailer is also called powder material transportation vehicle, which is suitable for bulk transportation of powdered materials with a diameter of less than 0.1mm, such as fly ash, cement, lime powder, ore powder, granular alkali and other particles.

The powder material transportation vehicle is a special-purpose vehicle. It is widely used in industry, agriculture, commerce, power plants, construction, etc.

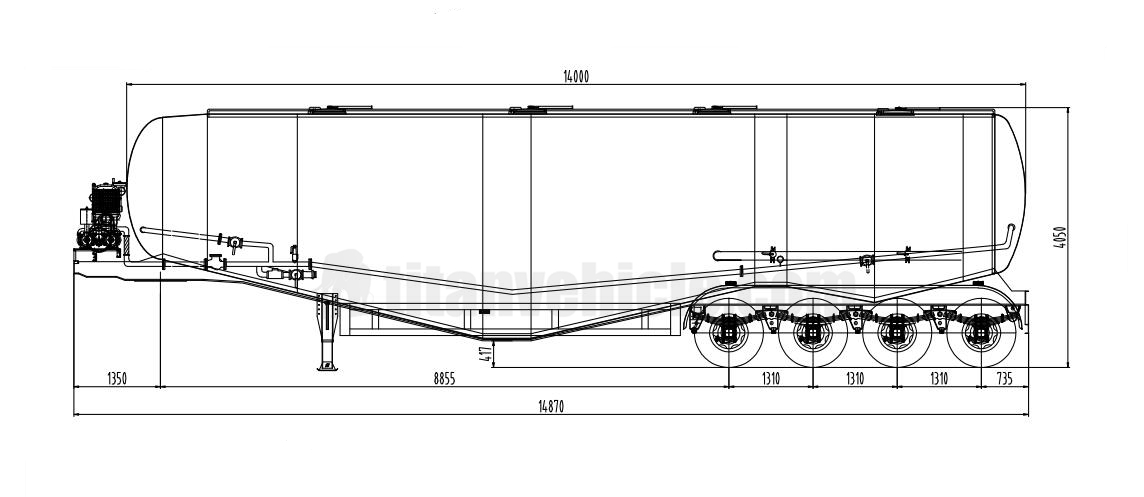

The following is the structural drawing of the 4 axle dry bulk cement tank trailer:

The main assembly of the powder tank truck is composed of a tank body, a power system (diesel engine, air compressor), a gas circuit system, and a brake system.

At present, the design of the fluidized bed in the tanks of TITAN Vehicle is scientific and the layout is reasonable, which can effectively shorten the discharge time and reach 1.4T / min.

The volume utilization rate of the tank is improved, and the residual ash rate is reduced, and the residual ash rate is 0.2%.

Power system:

TITAN cement bulker trailer uses world-famous brand diesel-engine Weichai 4102 to help the air compressor work better, the discharging speed can reach to 1.6ton per minute, the cement allowance is no more than 50kg.

Diesel engine and motor wave can be used to connect and drive through the secondary force device The shaft provides power input for the air compressor.

Single-cylinder or double cylinder air compressor is used to provide compressed air for discharge work, the pneumatic sand trailer rated working pressure is 0.2Mpa; the displacement is 10-14 cubic meters/min.

Tank body:

The powder tanker body is mainly composed of two oblique cones and front and rear heads. It is placed on the frame and serves as a carrier. The tank body is equipped with a feed inlet, a non-slip walking platform and a ladder for loading and maintenance personnel to enter the tank. The tank has slides, air chambers, discharge ports, etc., and the tank structure is V-shaped cement bulker, W-shaped silo semi trailer or straight shape cement tanker.

The V shape powder tanker trailer is a single silo tank, generally suitable for designing cubic numbers of 15-45m³. The W shape is a double-storage tank, generally suitable for designing cubic numbers of 50-75m³.

v shape VS w shape bulk cement tanker trailer

Piping system:

Intake pipe: After the gas is output by the air compressor, it enters each cabin through the check valve and the ball valve. A safety valve is installed before and after the check valve to prevent the pipeline pressure from being too high to damage the air compressor in case of an accident. The safety valve is set to bleed pressure to 0.2Mpa.

A pressure relief valve is installed on the top of the dry bulk tanker tank body to release the residual pressure in the tank, and is used for deflation before the user opens the material cover and stops discharging in the middle.

Unloading pipeline: The discharge pipeline is mainly composed of suction port, butterfly valve, discharge steel pipe, discharge pipe joint, discharge hose, etc.

An anti-shock pressure gauge is installed on the tank body to monitor the pressure change in the tank and to guide the discharge.

Working principle:

Use the equipped engine or borrow the host to drive the dry bulk trailer air compressor through the power take-off drive shaft or pulley, and send the compressed air into the air chamber of the sealed tank through the pipeline. When the pressure in the storage tank reaches the rated working pressure, open the discharge butterfly valve, and the powdery material will be discharged through the discharge system.

Before buying a silobas trailer, don’t just look at it and feel good. The unreasonable design of the tank body will affect the loading and unloading speed. This is one of the reasons why different manufacturers of the same size bulk powder trucks have different loading and unloading speeds. Different brands and matching of diesel and air compressor units will also affect the loading and unloading speed. High-quality diesel engines and air compressor devices are not only expensive issues. They are mainly used for occasions with few problems, fast speed and saving unloading time.

TITAN dry bulk cement tank trailer adopts high strength wear-resistant steel. To fabric the most durable tankers, especially for Africa Market, considering the road condition. This distortion resistance, earthquake resistance and bump, make your transport safety, also beneficial. more durable and more sturdy,it can ensure the tank very firm.

Through this video below, you can learn about different types of TITAN bulk cement tanker trailers, such as 3 axle dry bulk tanker trailer, 30-ton fly ash tanker, 50cbm silo trailer for sale.

And process, testing, packaging and customer feedback, etc.

If you want more information about our semi-trailer, please click “Cement Bulk Trailer“.

And you can also look at other articles and videos on our website.